HP Indigo W7250 driver and firmware

Drivers and firmware downloads for this Hewlett-Packard item

Related HP Indigo W7250 Manual Pages

Download the free PDF manual for HP Indigo W7250 and other HP manuals at ManualOwl.com

Charge Roller -- CA393-00080 Rev 07 - Page 9

... cover

3. Disconnect the solenoid connector, Figure 1-10 Rear solenoid connector

4. Remove the solenoid assembly. Figure 1-11 Removing the rear solenoid

5. Install the new solenoid assembly into position. 6. Connect the solenoid connector. 7. Install the solenoid connector cover. Use the three Phillips screws to fasten it to the charge roller

assembly. Replacing the rear...

Charge Roller -- CA393-00080 Rev 07 - Page 11

...solenoid to the charge roller assembly. 6. Remove the solenoid assembly.

Figure 1-16 Solenoid assembly

7. Install the new solenoid assembly into position. Fasten it to the charge roller assembly using the three ...Allen screws, washers and spring washers.

8. Connect the solenoid connector.

9. Install the solenoid connector cover. Use the Phillips screw to fasten it to the charge roller ...

Charge Roller -- CA393-00080 Rev 07 - Page 12

... instructions, and a notice of document confidentiality.

Revision history

Below is the history of the document revisions and a list of authors.

Revision

Description

CA393-00080 Rev00 Initial document

CA393-00080 Rev01 Updates

CA393-00080 Rev02 Add HP Indigo W7200 Digital Press to scope

CA393-00080 Rev03 Added the following press to scope: HP Indigo 7500 Digital Press, HP Indigo WS6000p...

IR Sensors Reading and Calibration -- CA393-09500 Rev 03 - Page 5

...the ITM

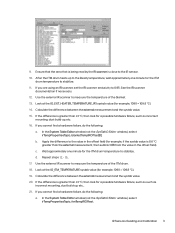

drum temperature to stabilize. 11. If you are using an IR scanner, set the IR scanner emissivity to 0.95. See the IR scanner

documentation if necessary. ... you cannot find a hardware failure, do the following:

a. In the System Table Editor window (not the SysTabIO Editor window), select irTempPropertiesTopic, blanketTempIROffset[0].

b. Apply the difference to the value in the offset field (...

Side Fog Troubleshooting - Page 11

...Do not hold the PIP underlayer while inching as this might cause it to stretch.

2. When installing the PIP foil, make sure that the PIP underlayer is made partially wet with imaging oil on a lint-free ...wipe.

3. When installing the PIP foil, use only imaging oil on the PIP foil trailing edge to prevent it from loosening...

Side Fog Troubleshooting - Page 12

... batch, that is, a different production year or a production week with a large difference from the installed PIP underlayer. 7. Check for side fog as described in "Checking for side fog on page 1" ... assembly. 2. Make sure that the housing springs are working correctly. 3. Make sure that the guide rails are not loose. 4. Verify that the charge roller housing rests completely on the three position...

Side Fog Troubleshooting - Page 14

.... 1. Check the press level. 2. If necessary, perform leveling as described in the press installation guide. 3. If any corrective action was taken above, check for side fog as described in "...-dripping cover

Refer to document CA393-10990 - Cleaning Station Side Fog and Anti-dripping Cover Installation.

Cleaning station unit

Refer below for Cleaning station unit. 1. Replace the cleaning station unit...

Dripping Prevention and ITM Heating Hood Service -- CA393-10100 Rev 00 - Page 2

... hood...14 Removing and installing the catch tray fan assembly...16 Removing and installing the IHH controller unit (for presses with external IHH controller 17 Wiring the dripping ... rate...33 IHH controller unit troubleshooting ...34 Baselining the dripping prevention kit ...36

Appendix A More theory ...63 Software settings ...63 Theory for presses without external IHH controller...63

Appendix B ...

Dripping Prevention and ITM Heating Hood Service -- CA393-10100 Rev 00 - Page 10

... before you begin the procedures. 1. Check the following SysTab parameter:

engineConfigTopic > ihhInstalled is set to HT_VER1, and bypassTableTopic > Ihh is set to FALSE, and engineConfigTopic > feedSuctionNautilairInstalled is set to TRUE. 2. Shut down the press software. 3. Shut down the power to the press.

Removing and installing the new ITM suction blower

Follow these steps to remove and...

Dripping Prevention and ITM Heating Hood Service -- CA393-10100 Rev 00 - Page 11

2. Install the new ITM suction blower in the press using the original 3 M6 Allen screws.

3. Verify that the rubber gasket is correctly positioned on the new ITM suction blower. (You can loosen the 3 screws at the top of the suction blower bracket, to allow adjusting the blower position, while connecting the rubber seal. Tighten the 3 screws when you are finished.)

8 Chapter 2 Procedures

Dripping Prevention and ITM Heating Hood Service -- CA393-10100 Rev 00 - Page 40

...Guide):

● Required ambient temperature 20 to 25° C (68 to 77° F) ● Required ambient relative humidity 50 to 70 percent non-condensing ● Required fresh air flow +150 cfm 2. Check chiller set...

Follow these steps to shutdown the press. 1. Shutdown the press software and computer. 2. Turn off the main power switch at the wall, and lock it in the OFF position. 3. ...

Dripping Prevention and ITM Heating Hood Service -- CA393-10100 Rev 00 - Page 66

A More theory

Software settings

The following software settings can be configured in the SysTab editor to support changes in the hardware configuration of your press. When installing the dripping reduction kit, set the following SysTab parameters: ● Set the parameter engineConfigTopic > ihhInstalled to HT_VER1. ● Set the parameter engineConfigTopic > feedSuctionNautilairInstalled to ...

Preventive Maintenance -- CA393-00660 Rev 08 - Page 3

... every 12 million impressions for HP Indigo WS6000 Series Digital Presses. NOTE: For HP Indigo WS6000 Series Digital Presses with press software v15.0 I-Fix 1 and above, reset the 12M IMP Counter when you are done. PM service will take place every 24 million impressions for HP Indigo WS7200 Series Digital Presses.

Estimated installation time

Estimated installation time is 6 hours.

Special jigs...

Preventive Maintenance -- CA393-00660 Rev 08 - Page 8

...the results according to HP Indigo WS6600 Digital Press Installation Manual (CA393-04361) or HP Indigo W7200 Digital Press Installation Manual (CA393-01570).

● Clear the hard drive (delete temporary and unused files) - see HP SmartStream Labels and Packaging Print Server, Powered by Esko Best Practice Guide (CA394-06791).

● Verify software configuration (HP IndigoServe, RIP, and Norton...

Preventive Maintenance -- CA393-00660 Rev 08 - Page 14

...control thermostat is approximately at the set point at 0.5°C.

● Check the state of the water filter. If the pressure drop exceeds 1 bar (10 psi), change the filter element.

ILD

● If ILD is installed...for HP

● Click Next.

Indigo WS6000 Series Digital Presses with ● Select Click Finish to confirm compilation of Customer Engineer 12M Imp maintenance.

press software ...

Preventive Maintenance -- CA393-00660 Rev 08 - Page 23

... leak

Appendix E - Replacing the Ametek blower air filter

There are two types of Ametek blower filters. Use the relevant procedure to remove the filter before installing the replacement filter.

Removing the Ametek blower filter (Type 1)

Refer below for the type of filter and follow the steps to remove the ametek blower...

Preventive Maintenance -- CA393-00660 Rev 08 - Page 24

...) as described below in

Installing an Ametek blower filter on page 23.

Removing the Ametek blower filter (Type 2)

Refer below for the type of filter and follow the steps to remove the ametek blower filter. 1. Shut down the press software. Turn off the press. 2. Insert a flat screw driver into the slot in the...

Preventive Maintenance -- CA393-00660 Rev 08 - Page 25

... blower filter as described below in Installing an Ametek blower filter on page 23.

Installing an Ametek blower filter

Follow the steps below for installing an ametek blower filter. 1. Shut down the press software. Turn off the press. 2. Insert the filter into the housing. Each pin should fit into a slot. (There are 8 pins and...

Preventive Maintenance -- CA393-00660 Rev 08 - Page 27

..., added HP Indigo W7200 Digital Press to the scope. Update of entire document content. HP Indigo W7250 Digital Press to the scope. Removal of kit and addition of inspection and cleaning of filters before replacing. Updates of part numbers. Updates of topics in tables. Line added to Ink Cabinet section. Added information about HP Indigo WS6000 Series Digital Presses with press software v15.0 I-Fix...

Long Term Shutdown for Indigo WS6000 Series Digital Presses and Indigo W7200 Series Digital Presses -- CA393-09200 Rev 01 - Page 7

... Digitax 9. Turn on the press and ILP (if installed). 10. Load a substrate roll on the unwinder. Load an empty core on the rewinder. 11. Replace all... Validate the ink conductivity. 14. Check that the writing head window and the IR sensors are clean. 15. Change the press ...Make sure that the press software is up-to-date. 19. Check with the Technical Group for any service notes that need to be implemented....