HP Scitex FB10000 driver and firmware

Drivers and firmware downloads for this Hewlett-Packard item

Related HP Scitex FB10000 Manual Pages

Download the free PDF manual for HP Scitex FB10000 and other HP manuals at ManualOwl.com

Geffen TS Error 50219 - Page 2

... is not UP

FB10000 Error Messages Troubleshooting

Recommended ... is OFF, use a small flathead screw driver to release the sensor's set

screw and slowly slide it along the piston...Control Tools -> Motion -> LB-Loader Suction-Cups Bar.

Mechanical Interference

1. Make sure that no object or dirt obstructs the movement of one of the pistons such as media waste, cable tie, dirt etc.

Top

2. If the error...

Geffen TS Error 66115 - Page 3

...FB10000 Error Messages Troubleshooting

7. Ask a colleague to monitor the Small Heater SSR LED [SSR_H1] while you perform the following tests: When cooler is idle, the SSR should be OFF, when cooler is running this Led should be lit.

SSR_H1 in Unified cooler electric panel

8. Start the Cooler from the Service Tool application window... error in the B&R module or in the Ethernet line.

B&R control ...

Site Preparation Guide Rev. 2 - Page 3

... are set forth in the express warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

This document is delivered subject to the following conditions and restrictions:

This document contains proprietary information of HP Scitex...

Site Preparation Guide Rev. 2 - Page 5

...HP Scitex FB10000 Site Preparation Guide since the initial release in October 2013.

Revision 2 - June 2014

Updated... Substrates on page 41. Added instructions regarding the temperature around the unified...list of supported RIP Applications on page 49. Updated the ...FB10000 Layout on page 78 to include space requirements for a possible future upgrade to the HP Scitex 15000 Corrugated Press.

Preface

iii

Site Preparation Guide Rev. 2 - Page 7

...Guide ...2

HP Scitex FB10000 Industrial Press 2

Site Preparation Overview ...4

Installation Time Schedule ...5

Chapter 2 Customer Responsibilities

7

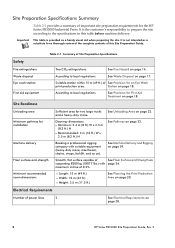

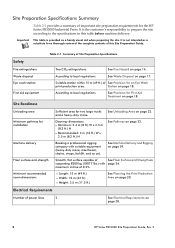

Site Preparation Specifications Summary 8

HP Scitex FB10000 Industrial Press Machine Views 11

HP Scitex FB10000... 24

Positioning Peripheral Components 25

Protecting Pipes and Cables 26

Danger Zone and Warning Labels 27

Electrical Requirements ...

Site Preparation Guide Rev. 2 - Page 9

CHAPTER

1

Introduction

About This Guide 2 HP Scitex FB10000 Industrial Press 2 Site Preparation Overview 4 Installation Time Schedule 5

Site Preparation Guide Rev. 2 - Page 10

About This Guide

This guide is intended for customers installing the HP Scitex FB10000 Industrial Press, printer operators, HP Service personnel and HP dealers.

This document guides the customer through the site preparation required prior to receiving and installing the HP Scitex FB10000 Industrial Press. It details site preparation instructions, including important environmental and safety ...

Site Preparation Guide Rev. 2 - Page 12

...

The information provided in this guide covers all aspects of HP Scitex FB10000 Industrial Press site preparation, and has been included to assist in the following planning considerations:

• Modifications to the installation area, if required.

• Accessibility to the site; providing suitable access through driveways, corridors, doorways, and loading bays.

• Provision of suitable...

Site Preparation Guide Rev. 2 - Page 13

...

The optimal time required for installing the HP Scitex FB10000 Industrial Press system is 10 working days:

1st week - Leader and one HP Scitex Customer Engineer (CE)

2nd week - Leader and Application Specialist

This is based on the assumption that all system parts have been delivered in proper working ...

Site Preparation Guide Rev. 2 - Page 16

... pathway for installation

Machine delivery

...supporting 8200 kg (18077 lbs.) with page 24.

maximum incline of 0.2%.

• Length: 15 m (49 ft.) • Width: 10 m (33 ft.) • Height: 3.5 m (11.5 ft.)

See Planning the Print Production Area on page 20.

Electrical Requirements

Number of power lines

2

See Electrical Requirements on page 28.

8

HP Scitex FB10000 Site Preparation Guide...

Site Preparation Guide Rev. 2 - Page 18

... Open ports

• RIP station to machine PC: RJ-45 Ethernet cable (20 m max. length)

• Machine computer to customer network (internet)

See Networking Requirements on page 48.

Required for Call Me @ HP remote See Call Me @ HP - Web Based

support.

Remote Support on page 50.

RIP Requirements

RIP station hardware

Workstation that meets the RIP software specifications (PC/Mac).

See...

Site Preparation Guide Rev. 2 - Page 24

General

• The printer is designed and manufactured to ensure maximum safety operation. It should be installed, operated, and maintained by qualified users (authorized by HP Scitex) in strict compliance with the safety precautions, warnings, and operating instructions contained in the HP Scitex FB10000 Operator Manual.

• The HP Scitex FB10000 Industrial Press has been designed to meet ...

Site Preparation Guide Rev. 2 - Page 26

...storage and disposal requirements for wastes associated with the printer. Waste containers should not be discharged in sewers and are banned from landfill sites.

Provision for an Eye Wash Station

When installing the HP Scitex FB10000... at all times. The services of a plumber will be required for installation of the types of eye...installation.

18

HP Scitex FB10000 Site Preparation Guide, Rev. 2

Site Preparation Guide Rev. 2 - Page 28

... at all times, is imperative.

• You should consider allocating additional floor space for operators, ink fill area, service area, maintenance area and for handling prints.

For a sample floor plan of the FB10000 press and its external components (the drawings are to scale), see FB10000 Layout on page 78.

20

HP Scitex FB10000 Site Preparation Guide, Rev. 2

Site Preparation Guide Rev. 2 - Page 29

... to installation. The print production area in particular should be free from dirt and dust.

Due to regulations the floor should be concrete. Tiles floors are not recommended. Wood and metal floors are not allowed.

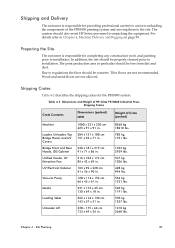

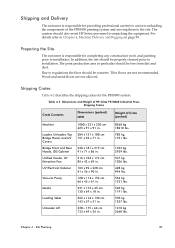

Shipping Crates

Table 4-2 describes the shipping crates for the FB10000 system.

Table 4-2 Dimensions and Weight of HP Scitex FB10000 Industrial...

Site Preparation Guide Rev. 2 - Page 30

... be available on the day required to lift and convey the equipment from the truck to the unpacking area - or alternatively to a predetermined temporary storage area - and thereafter to the installation site.

For details of lifting and conveying equipment requirements, see Required Tools and Equipment on page 61.

22

HP Scitex FB10000 Site Preparation Guide, Rev. 2

Site Preparation Guide Rev. 2 - Page 32

... to support the entire weight of the printer, including all accompanying equipment (see Figure 4-1). A construction engineer should be consulted regarding the load-bearing capabilities of the floor of the building where the FB10000 press is to be installed.

Note Installation of the machine loader requires drilling ten (10) holes into the floor.

24

HP Scitex FB10000 Site Preparation Guide, Rev...

Site Preparation Guide Rev. 2 - Page 34

... will be required in a separate area for the storage of inks and substrates, as described in Storage Area for Consumables and Substrates on page 41.

Protecting Pipes and Cables

It is the customer's responsibility to protect the pipes and cables that connect the external components to the HP Scitex FB10000 Industrial Press with a secure, metal cover (height...

Site Preparation Guide Rev. 2 - Page 56

... In such cases, the RIP workstation requires two Ethernet ports, one port for the crossover cable and another port to connect the workstation to the network.

• The customer should install antivirus software to protect the RIP workstation.

• It is the customer's responsibility to protect the network cables from any lightning hazard.

48

HP Scitex FB10000 Site Preparation Guide, Rev. 2

Site Preparation Guide Rev. 2 - Page 85

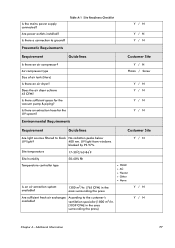

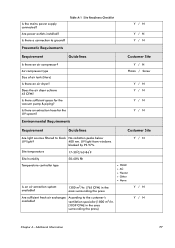

Table A-1 Site Readiness Checklist Is the mains power supply connected? Are power outlets installed? Is there a connection to ground?

Pneumatic Requirements

Y / N

Y / N Y / N

Requirement...peaks below

UV light?

400 nm. UV light from windows

blocked by 99.97%.

Site temperature

17-30°C/63-86°F

Site humidity

50-60% Rh

Temperature controller type

• HVAC • AC • ...