Brother International BE-0901E-AC driver and firmware

Drivers and firmware downloads for this Brother International item

Related Brother International BE-0901E-AC Manual Pages

Download the free PDF manual for Brother International BE-0901E-AC and other Brother International manuals at ManualOwl.com

Thread Tensions - English - Page 1

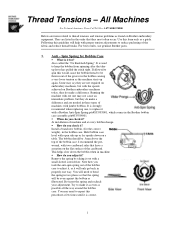

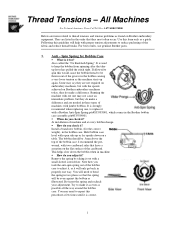

... tension problems as found on Brother embroidery equipment. They are listed in the order that they most often occur. Use this form only as a guide. Following this guideline will help...a Brother Anti-Spin Spring p/n#S35583001, which comes in the Brother bobbin case assembly p/n#S35584001. !" When do you check it? At installation of machine and at every bobbin change. !" How do you check it? Install a...

Thread Tensions - English - Page 2

...constant, works with top thread to form a proper stitch. !" When do you check it?

At install and at every bobbin change. When tensions are believed to be the problem,

ALWAYS check and adjust ...tension

gauge. The guage will take into account the

pressure of the anti-spin spring while setting

the tension. Adjust the bobbin tension after

adjusting the anti-spin spring and cleaning

under the ...

Thread Tensions - English - Page 3

...-4BROTHER

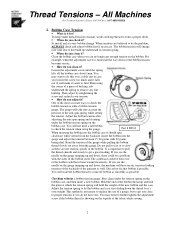

3. Main Tensioners

!" What are they for? Main upper thread tension control of machine. !" When do you adjust them? At install, then only after bobbin has been cleaned and adjusted first. Run a tension test first, if you are still having trouble check the thread path and rethread the complete path for the troublesome...

Knife Adjustments - English - Page 3

... machine and re-check the adjustment. You may have to do this more than once to achieve the correct position.

Moving Knife Adjustment Screws

Re-install the arm cover and the needle plate and your finished. If you find that the machine will still not cut the thread cleanly, you might...

Creating Version Disks - English - Page 1

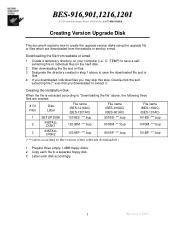

...916AC) (BES-901AC)

File name (BES-116AC) (BES-101AC)

1

SETUP DISK

1201BS -***.bup

901BS -***.bup

101BS -***.bup

2

INSTALL DISK1

1201BM -***.bup

901BM -***.bup

101BM -***.bup

3

INSTALL DISK2

1201BP -***.bup

901BP -***.bup

101BP -***.bup

(***varies according to the version of the software downloaded.)

1. Prepare three empty 1.4MB floppy disks. 2. Copy each file to a separate floppy...

Machine Settings - English - Page 3

...number from 1 - 5 (1= fast, 5=slow). Default setting is 1. Recommended setting is 2.

Second page of settings

Data transfer speed - Communication speed with computer when using the download cable.

Default setting is 38400. Recommended setting is 38400.

Display language - what language is used on the display panel.

Default setting is ENGLISH. Recommended setting is ENGLISH.

Alarm sound - This is how...

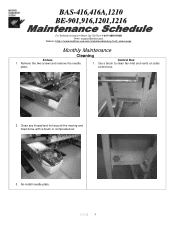

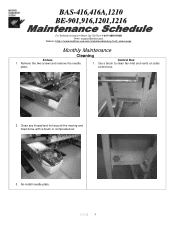

Maintenance Schedule - English - Page 3

...://www.brother-usa.com/industembroidery/tech_down.aspx

Monthly Maintenance

Cleaning

Knives 1. Remove the two screws and remove the needle

plate.

Control Box 1. Use a brush to clean fan inlet and vents on sides

control box.

2. Clean any thread and lint around the moving and fixed knive with a brush or compressed air

3. Re-install needle plate...

Maintenance Schedule - English - Page 6

...Email: tsupport@brother.com

Website: http://www.brother-usa.com/...guide bracket and retracting lever as indicated by the arrows.

X sensor eccentric bushing 1. Remove the 8 screws holding on the cover and

remove.

2. Lubricate eccentric bushing with a few drops of oil to the slot as indicated by the arrow.

3. Install the cover. Note: Make sure that the wires that run up to the control...

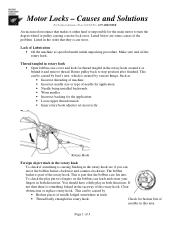

Motor Locks - English - Page 1

... for the main motor to turn the degree wheel or pulley causing a motor lock error. Listed below are some causes of the problem. Listed in the order that they occur... application • Needle being installed backwards • Worn needles • Incorrect backing for the application. • Loose upper thread tension • Inner rotary hook adjuster set incorrectly

Rotary Hook

Foreign object...

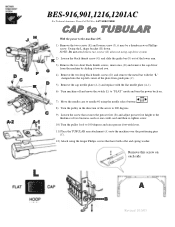

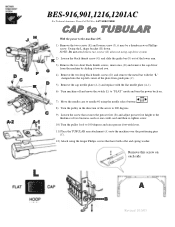

Cap to Tubular - English - Page 1

... cap drive system

2) Loosen the black thumb screw (G) and slide the guide bar (F) out of the lower arm.

3) Remove the two short black thumb screws, inner ones, (E) and remove the cap driver from the...the plate from guide pins (C).

5) Remove the cap needle plate (A-2) and replace with the flat needle plate (A-1).

6) Turn machine off and move the switch (L) to "FLAT" mode and turn the power back on....

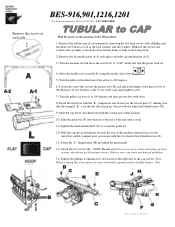

Tubular To Cap - English - Page 1

... and move the switch (L) to "CAP" mode and turn the power back on.

4) Move the needle case to needle #1 using the...Install the metal bar with the "L" stamped on and attach over the locator pins (C) making sure that the stamped "L" is on the left side facing up. Secure with the long black thumbscrews (D).

9) Slide the cap driver attachment through the sewing arm of the machine.

10) Slide the guide...

Version Upgrade - English - Page 1

...,1201

For Technical Assistance Please Call Toll Free 1-877-4BROTHER

Upgrading the version

1. Turn on the power of the machine. 2. After the home position is detected, the standby screen appears.

3. Press twice while the standby screen is displayed.

4. Select the version upgrade icon with , and press .

5. The password input screen appears. Input "961", and press .

6. The OK...

Version Upgrade - English - Page 2

... wrong, and press .

11. Installation of the disk 1 starts. 12. After the installation of the disk 1 has completed, the screen displays as follows. Insert the disk 2, and press .

13. Installation of the disk 2 starts. When there are four version upgrade floppy disks in a set, the screen displays as follows after the installation of the disk 2 has completed. Insert the disk 3, and press . When there...

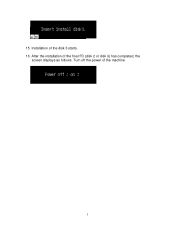

Version Upgrade - English - Page 3

15. Installation of the disk 3 starts. 16. After the installation of the final FD (disk 2 or disk 3) has completed, the

screen displays as follows. Turn off the power of the machine.

3

Upper Thread Breaks - English - Page 1

... thread is not threaded correctly o Correctly thread the machine

• Upper thread tension is to tight o Reduce upper thread tension

• Needle is not installed correctly o Install needle correctly

• Needle is bent or worn o Replace the needle

• Presser foot height is incorrect o Adjust presser foot height to thickness of material...

Programming the machine settings - English - Page 14

Please note that some icons may appear differently on your machine panel, due to possible updates or changes in current machine firmware, (version 5.12 as of January 2009).

For help or questions about these settings, please contact Brother Technical Service at 877-427-6843, or email Brother Technical Support at: tsupport@brother.com

14

Head Board Replacement - English - Page 3

... install the new one. A. Installing board - Please follow reverse instructions on removal. B. Make sure that the rotary switch on the board is set to 1.

8. After board is installed and all plugged in you will need to perform a version up-grade in accordance to model of machine. (For version up-grading machine please follow version upgrade procedure.)

9. After board is installed, machine is version...

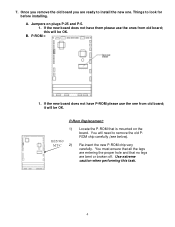

Main Board Replacement - English - Page 4

... one. Things to look for before installing.

A. Jumpers on plugs P-25 and P-5. 1. If the new board does not have them please use the ones from old board; this will be OK.

B. P-ROM =

1. If the new board does not have P-ROM please use the one from old board; it will be OK.

P-Rom Replacement:

1)

BES 960 MT-C 2)

Locate the...

Main Board Replacement - English - Page 5

Be sure to align the U-shape cut out to the socket mount.

8. Installing board, please follow reverse instructions on removal. 9. After board is installed and all plugged in you will need to perform a version up-grade in

accordance with the model of machine. The machine will act like it is in-operative until this step is performed...

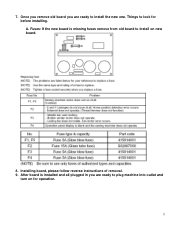

Power Supply Replacement - English - Page 3

7. Once you remove old board you are ready to install the new one. Things to look for before installing. A. Fuses: If the new board is missing fuses remove from old board to install on new board.

8. Installing board, please follow reverse instructions of removal. 9. After board is installed and all plugged in you are ready to plug machine into outlet and

turn on for operation.

3